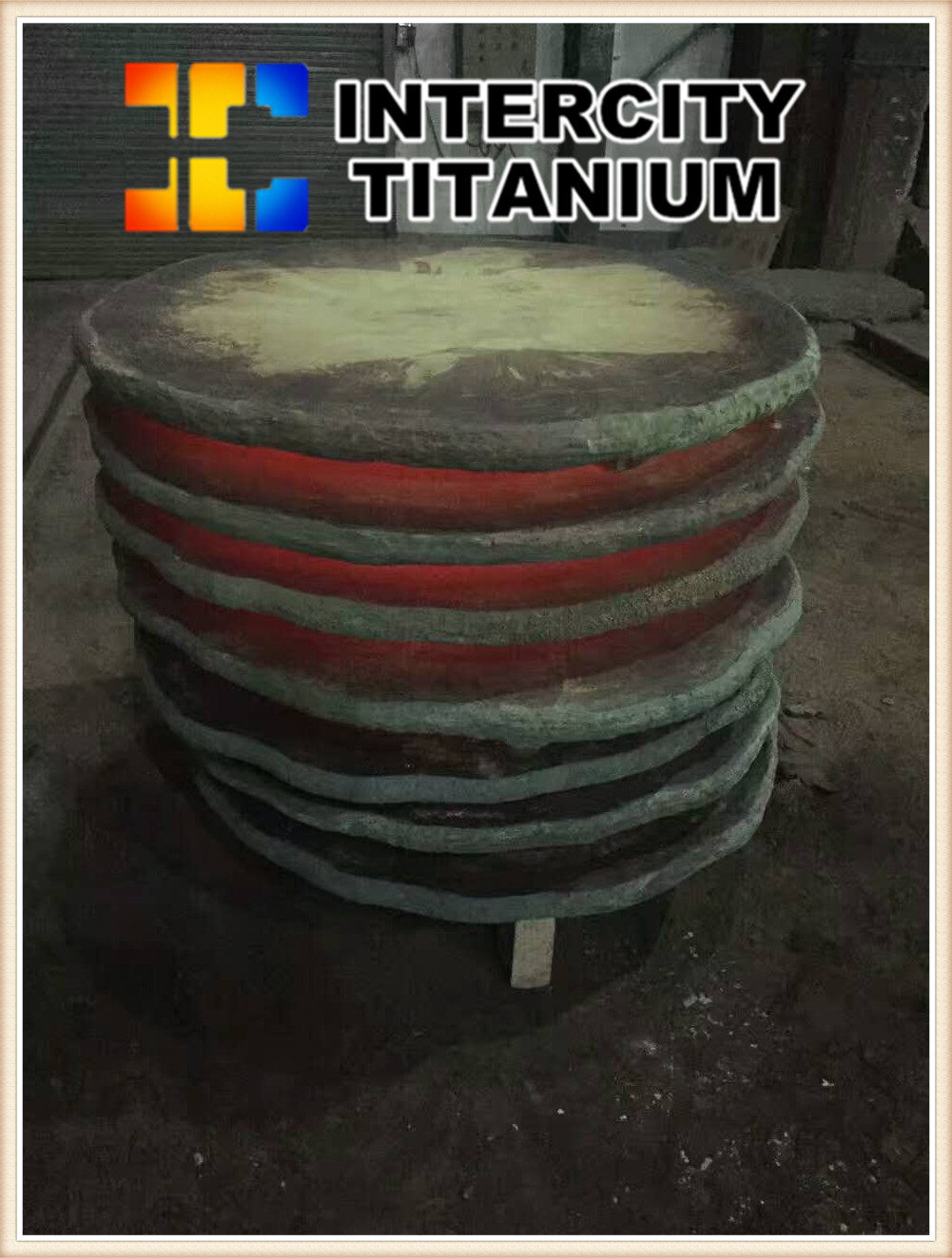

Forging process of titanium alloy

Forging is one of the two major components of forging (forging and stamping) that utilise a forging machine to apply pressure to a metal blank to cause it to plastically deform to achieve mechanical properties, a processing method of a certain shape and size forgings.

In addition, depending on the way in which the slide is moved and how the vertical and horizontal movement of the slide (forging of the slender parts, lubrication cooling and high-speed production of parts), the compensating device can increase the movement in other directions. The above methods are different, the required forging force, process, material utilization, yield, dimensional tolerance and lubrication cooling are not the same, these factors are also factors that affect the level of automation.

According to the movement of billets, forging can be divided into free forging, upsetting, extrusion, forging, closed forging, closed upsetting. Closed die forging and closed upsetting as there is no flash, material utilization is high. a process or a few processes may be completed complex forging finishing. As there is not any flash, the forging area decreases, the required load is also reduced. However, care should be taken not to limit the billet to a maximum extent, for which purpose the billet size should be carefully controlled, the relative position of the forging die controlled and the forgings measured, in an effort to reduce die wear.

According to the forging die movement, forging can be separated into the roller, swivel forging, roller forging, cross wedge rolling, rolling ring and oblique rolling and other means.

Rolling, swaging and rolling rings can be used for precision machining. In order to increase the utilization of materials, roll forging and cross-rolling can be used as slender material before the process of processing. Rotary forging, as with uncontrolled forging, is also partially formed and has the advantage of being formed in a less forged condition compared to forgings. Including free forging, including this forging method, the processing of materials from the mold surface to the free surface near the expansion, it is difficult to ensure the accuracy, therefore, the direction of the forging die and swaging process using computer control, you can use the lower Forging force to obtain complex shape, high precision products, such as the production of many varieties, large size turbine blades and other forgings.

In order to obtain high accuracy, care should be taken to prevent overloading at bottom dead center, control of speed and die position. Because these will be forgings tolerance, shape accuracy and die life has an impact. In addition, in order to maintain accuracy, care should be taken in order to adjust the slider rail clearance, to ensure rigidity, adjust the bottom dead center and the use of subsidies for transmission and other measures.

Titanium forging materials are mainly composed of various components of pure titanium and titanium alloy, the original state of the material bar, ingot, metal powder and liquid metal. Metal deformation in the cross-sectional area and the deformation of the cross-sectional area ratio called the forging ratio. Correct choice of forging ratio, reasonable heating temperature and holding time, a reasonable forging temperature and final forging temperature, a reasonable amount of deformation and deformation speed to improve product quality, decrease costs have a great relationship.

Forging is one of the two major components of forging (forging and stamping) that utilise a forging machine to apply pressure to a metal blank to cause it to plastically deform to achieve mechanical properties, a processing method of a certain shape and size forgings.

In addition, depending on the way in which the slide is moved and how the vertical and horizontal movement of the slide (forging of the slender parts, lubrication cooling and high-speed production of parts), the compensating device can increase the movement in other directions. The above methods are different, the required forging force, process, material utilization, yield, dimensional tolerance and lubrication cooling are not the same, these factors are also factors that affect the level of automation.

According to the movement of billets, forging can be divided into free forging, upsetting, extrusion, forging, closed forging, closed upsetting. Closed die forging and closed upsetting as there is no flash, material utilization is high. a process or a few processes may be completed complex forging finishing. As there is not any flash, the forging area decreases, the required load is also reduced. However, care should be taken not to limit the billet to a maximum extent, for which purpose the billet size should be carefully controlled, the relative position of the forging die controlled and the forgings measured, in an effort to reduce die wear.

According to the forging die movement, forging can be separated into the roller, swivel forging, roller forging, cross wedge rolling, rolling ring and oblique rolling and other means.

Rolling, swaging and rolling rings can be used for precision machining. In order to increase the utilization of materials, roll forging and cross-rolling can be used as slender material before the process of processing. Rotary forging, as with uncontrolled forging, is also partially formed and has the advantage of being formed in a less forged condition compared to forgings. Including free forging, including this forging method, the processing of materials from the mold surface to the free surface near the expansion, it is difficult to ensure the accuracy, therefore, the direction of the forging die and swaging process using computer control, you can use the lower Forging force to obtain complex shape, high precision products, such as the production of many varieties, large size turbine blades and other forgings.

In order to obtain high accuracy, care should be taken to prevent overloading at bottom dead center, control of speed and die position. Because these will be forgings tolerance, shape accuracy and die life has an impact. In addition, in order to maintain accuracy, care should be taken in order to adjust the slider rail clearance, to ensure rigidity, adjust the bottom dead center and the use of subsidies for transmission and other measures.

Titanium forging materials are mainly composed of various components of pure titanium and titanium alloy, the original state of the material bar, ingot, metal powder and liquid metal. Metal deformation in the cross-sectional area and the deformation of the cross-sectional area ratio called the forging ratio. Correct choice of forging ratio, reasonable heating temperature and holding time, a reasonable forging temperature and final forging temperature, a reasonable amount of deformation and deformation speed to improve product quality, decrease costs have a great relationship.

Small and medium-sized forgings are generally round or square bar as a billet. Bar material grain and mechanical properties of uniform, good, accurate shape and size, surface quality, ease of mass production organizations. As long as the reasonable control of the heating temperature and deformation conditions, without the need for large forging deformation will be able to forge a good performance forging.