The metal composite material is a raw material obtained by combining two or more kinds of monomer raw materials having different chemical properties, or a new raw material prepared by compounding treatment by the raw matrix material and the reinforcing raw material. Compared with the monomer raw materials, the function of composite materials has many common places, its primary strength is the mechanical function, physical function or chemical function can be satisfied with the specific functional requirements or reduce costs, which is the monomer raw materials can not be achieved.

Titanium composite materials have many types, such as titanium steel composite panels, titanium-copper rods, titanium and titanium steel transition joints, titanium composite materials can not only meet the needs of users, and the price is lower than pure titanium or Chin alloy, Welcomed by the mall. Such as titanium steel composite board, both with the strength of steel, but also has the corrosion resistance of titanium, commonly used in metallurgical and chemical equipment production.

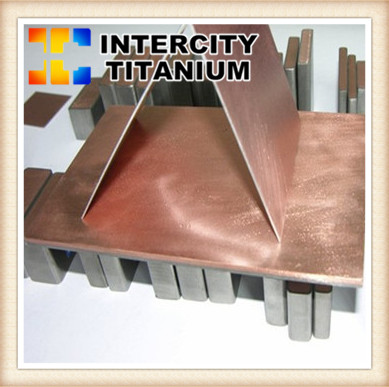

Titanium copper composite rod is commonly known as titanium copper rods. The metal anode of the electrolytic cell is backed by a titanium copper composite rod, and its effect is 3 points: one is the support anode; the second is the conductive; the third is the corrosion resistance. In order to respond to these needs, the use of titanium corrosion resistance and copper conductivity, the two linked together. Composite bar is copper in the middle, outsourcing a layer of titanium, cross-section with a square and palace-shaped two, completely satisfied with the use of demand. Titanium copper composite billet in the extrusion process by the strong pressure, the two metal interface constitutes a metallurgical contact, the waveform interface is the best way to contact the two metals, and then enhance the titanium-copper composite rod contact reliability, the resistivity Small, good conductive function. Overseas development of a titanium-copper composite pipe, copper outside the titanium, its strength is to save copper, good corrosion resistance.

Blasting welding transition joints have a high contact strength and low contact interface resistance, utilized in the industrial sector to enhance production, improve efficiency and save energy. The current research and development of titanium copper, titanium stainless steel, titanium steel, aluminum stainless steel, aluminum titanium stainless steel, aluminum and copper and other transition joints. Whether the plate is still tubular metal transition joints, can be obtained from the appropriate scale of the plate, but usually the transition joints used in stress, hot and cold shock and high current parts, it requires a higher contact strength and excellent Of the conductive function. Selection of improved flat-panel blasting composite technology can be achieved with high strength, low interface resistance of the bimetallic and three metal materials, the transition joints.