Improve the uniformity of titanium alloy free forging. First of all, in the rolling of titanium alloy large-size bar production process, due to less deformation path, the original slab thick, uneven organization often cannot be fully and effectively improved. Bar tissue at low magnification is prone to coarse grains and non-uniform. At the same time, prevent this asymmetrical structure in the titanium alloy. In the process of smelting and solidifying titanium alloy, due to the equilibrium distribution coefficient of all kinds of alloying elements is not equal to 1, α-stable elements are enriched and segregated at the post-solidified grain boundaries, so the α phase is precipitated first and precipitated along the crystal Boundary to the growth of intracrystalline, thus forming a large α block, micro-composition segregation is the root cause of this uneven structure. Third, to break the columnar crystals, to improve macrosegregation, the as-cast microstructure into the organization, and the appropriate conditions of temperature and stress welding internal pores, thereby continuously improve the density of the material. Through these measures can be forging impact toughness, fatigue strength and long-lasting performance, etc. have also been enhanced, and then by the final heat treatment of parts can get the required hardness of the parts, strength and good overall performance. Prevent performance defects. First, the dominant thermal effect during forging must be considered. Can not hit the billet continuously.

Forging titanium alloy under the conditions of the proposed press or fast forging machine, this type of forging equipment to combat speed is low, the blank forging process transient strain rate is low, the deformation heat is not very obvious, and have enough time to deformation Thermal diffusion does not result in a significant increase in the instantaneous temperature of the heart. Secondly, the use of pre-formed or upset forged, to increase the top, root and burr edge of the bridge groove and the junction of the fillet radius, increase the degree of internal and external mold forging and other measures can help avoid sharp turn in the metal flow process and Caused the above defects. Third, titanium and titanium alloy deformation resistance, forging temperature and the sensitivity of the defect.

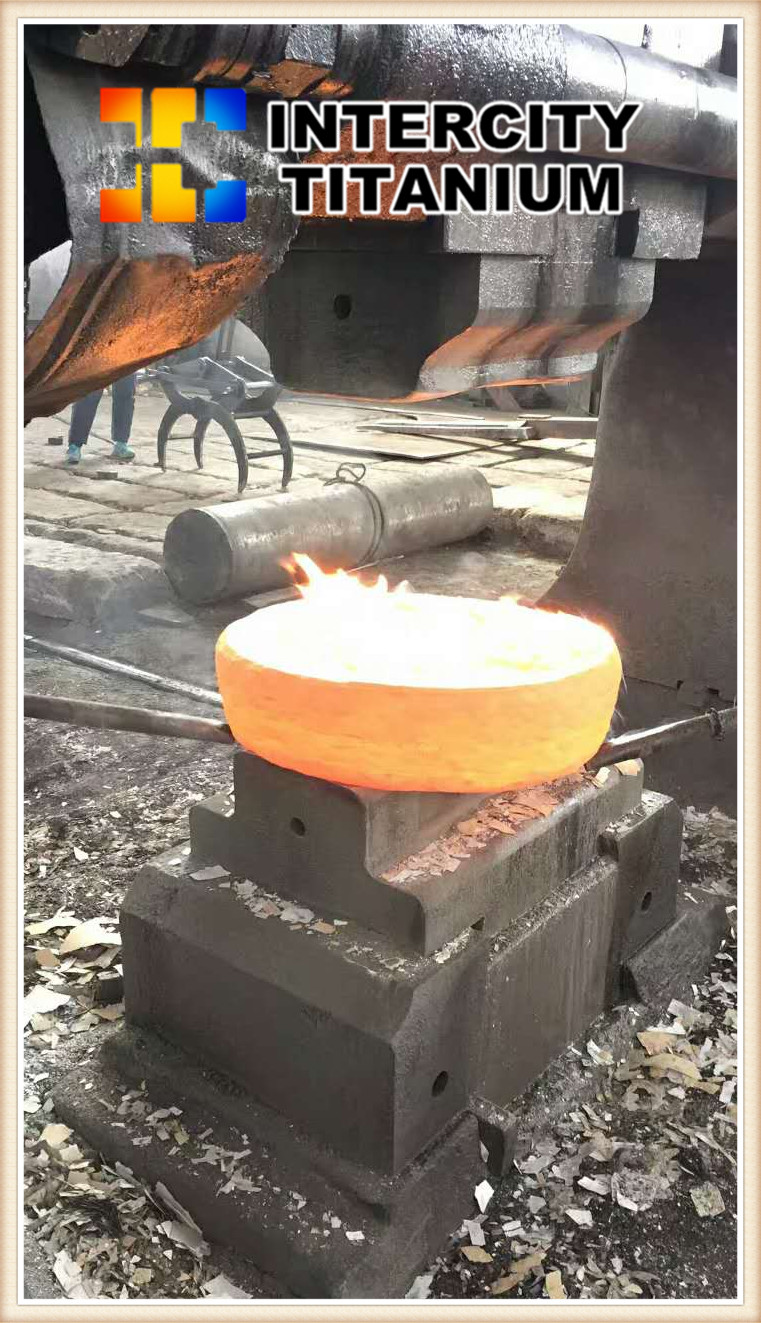

Titanium heating to prevent pollution, the general use of electric furnace, induction furnace, with a gas furnace heating flame cannot be directly sprayed onto the metal surface. Titanium forging temperature is generally controlled between 800-1150, the heating temperature should not be high, the time should not be long, otherwise easy to gas pollution, hydrogen absorption, oxygen, the grain coarse forging quality. Prevent crack defects. First, the mold should be preheated. Preheating the mold for the forging smooth, and reduce the metal forging process temperature, especially to decrease the billet surface chill, forging titanium alloy mold needs preheating. Otherwise, the metal's temperature drop and surface chilling will make the metal not well fill the mold groove and may cause many cracks. Die preheating systems for titanium alloy forging are usually detachable, but sometimes they are also provided with a heating device on the press. Detachable mold heating systems are usually gas heaters that slowly heat the mold to the desired temperature range before the module is assembled to the forging equipment. Stressed in the press on the heating device is usually induction heating or resistance heating. Second, we must repeatedly upset. It is forged in 80 ~ 120 above the temperature of the β transformation point. Alternately upsetting and drawing for 2 to 3 times while alternately changing axes and edges. This results in a very uniform uncrystallized fine-grained microstructure with β-zone deformation characteristics across the entire cross-section of the tank. Such as rough rolling mill, may not need to make such a multi-upsetting. Third, when forging, the corners of the fastest cooling. Therefore, the length must be repeatedly turned rough, and adjust the hammer force, so as to prevent acute angle. Forging hammer, the initial stage to be fought, the deformation does not exceed 5% to 8%, then you can gradually increase the number of deformation. In recent years, titanium alloy has rapidly developed into a new type of key structural material with strong vitality because of its superior specific strength, excellent corrosion resistance, good biocompatibility and so on. It is widely used in aerospace, military industry, Petroleum Chemical and medical and other fields. Therefore, to strengthen the formation of titanium alloy forging defects, and take effective preventive measures has been a very important value.