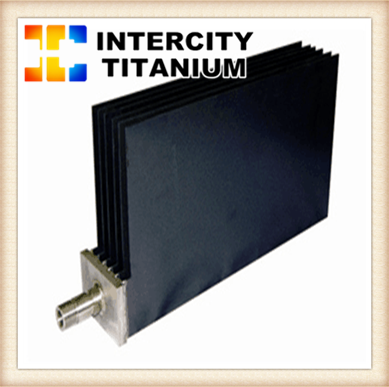

Ruthenium iridium coated titanium electrode

Generally in the precious metal plating, the use of titanium-based platinum-insoluble anode, it has high stability and corrosion resistance, can be utilized to a variety of media, and easy to maintain and manage. Due to the high price, the popularization and promotion, are limited.

Ru Ruthenium iridium electrode also known as metal anode, DSA (dimensionally stable anode), this article refers to the titanium coating Ru, Ir.

In the plating of gold, they utilize the DSA coated electrode, compared with the titanium-based platinum plating electrode, economical and practical, the price is 1/3 to 1/4 of titanium-based platinum plating. Ruhr coated titanium electrode has excellent electrochemical activity and corrosion resistance, suitable for a variety of media bath. Oxygen over-potential is high, not easy to passivation.

1. Acid gold plating:

In acid gold plating: Au (added as KAu (CN) 2) 8g / L, KSb (C4H406) 3 0.05g / L, (NH4) 3C6H5O7 80g / L, pH 4.6-4.8, / dm2.

When using a gold anode plate:

(1) the anode is easy to get rid of fine residue, loss of gold;

(2) consumption of completing agent, bath instability, frequent adjustments;

(3) anode passivation (tea yellow), scrub loss of gold.

When using titanium-based platinum plating:

(1) Easy to make Au + Au3 +, reduce the current efficiency;

(2) oxidative destruction of citric acid buffer, the bath is not stable enough;

(3) is expensive 3 to 4 time DSA.

After more than 6 months of uses of ruthenium-coated titanium electrodes, there was no change in ruthenium-coated titanium electrodes and no passivation phenomenon.

2. Rhodium-plated and nickel-plated, impact

(1) rhodium plating: Rh + 3 3g / L, H2SO4 40 ~ 60ml / L, room temperature, 2 ~ 3 A / dm2. Use six months, coated ruthenium titanium electrode is quite stable, no change in bath. Plating with titanium-based platinum plated electrode surface condition of the workpiece, there is not any difference.

(2) Nickel impact plating: HC1 100ml / L, NiC12 6H2O 200g / L, room temperature, 7 ~ 10 A / cm. In a large current, the use of one month without exception.

DSA electrode cost-effective than the titanium-based platinum electrode, the same performance requirements. Therefore, it is worth to promote the application of fresh bath and sewage treatment.