Titanium alloy forging common defects

Titanium alloy has been one of the most promising metal structural materials in the contemporary aerospace field due to its excellent combination of low density, high specific strength, high-temperature resistance, corrosion resistance and non-magnetic properties. With the large amount of application of titanium alloy, its metallurgical quality problems are also increasingly aroused widespread concern in the industry, so the quality of titanium alloy is increasingly important.

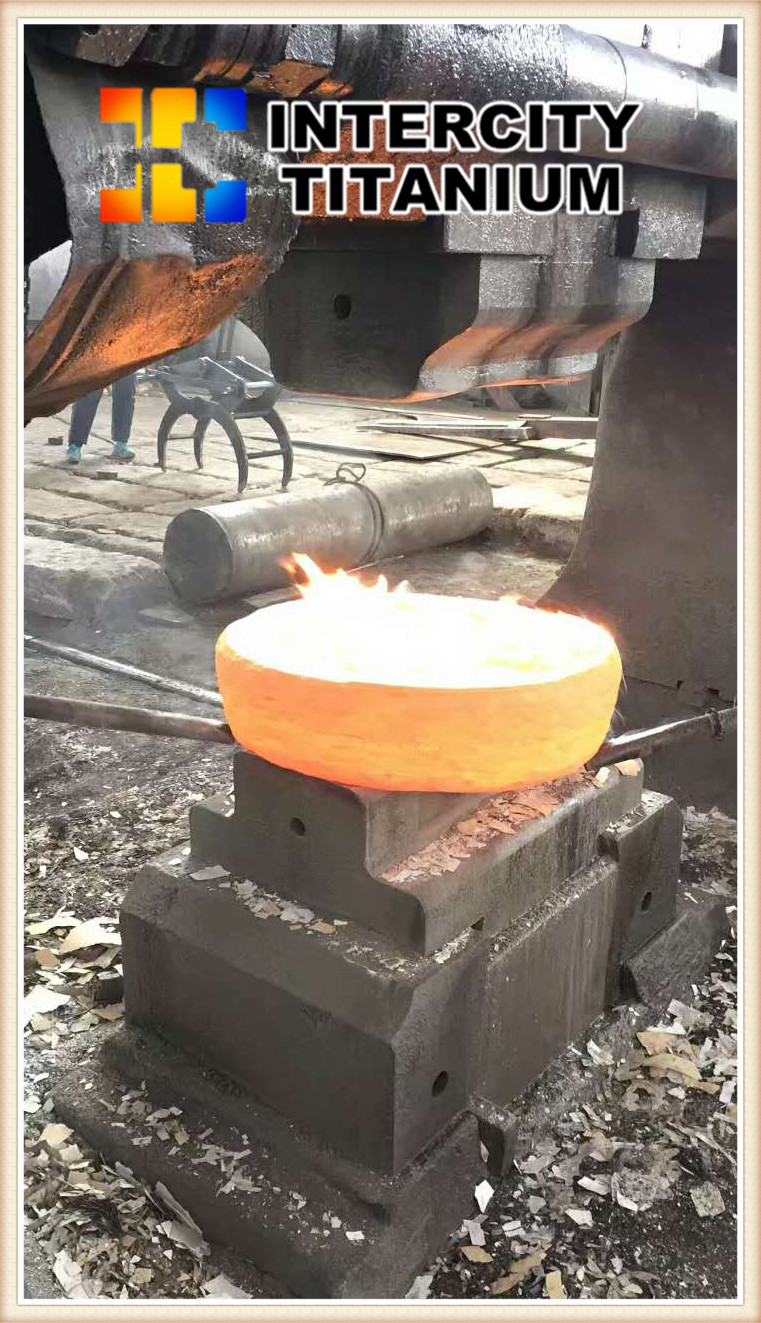

At present, more than 80% of industrial titanium alloys are used for deformed titanium alloy, such as forgings, forged rods and rolled profiles. Forging deformation is the most important thing means to ensure the ideal microstructure and properties of titanium alloy. However, the incorrect forging process often leads to some undesirable microstructure and metallurgy defects in the titanium alloy, which deteriorates the mechanical properties of the titanium alloy. The potential harm caused by the normal use, while causing a lot of waste in the production and use of the manufacturers, so the analysis of the formation mechanism of various titanium alloys forging defects, and take effective preventive measures has a very important value.

At present, common forging defects in titanium alloys are mainly overheated and uneven structure, cavities and cracks. These defects are usually easily found in the microstructure inspection or ultrasonic testing of titanium alloy products, mainly in the forging process of titanium alloy products Therefore, the suitable deformation rate (forging equipment), heating forging temperature, the amount of deformation of the pass and the cooling rate after forging are selected according to the different characteristics of the titanium alloy during the forging process.

The company is located in:

Hollow-type defects

The results show that the deformation of the metal material is accompanied by the change of the microstructure during the plastic deformation, including the grain growth, equiaxed crystal elongation, grain rotation and sliding, dislocation proliferation, dynamic recovery and recrystallization, cavitation and nucleation Big and so on. Grain boundary slip is the main mechanism of plastic deformation, grain boundary slip will cause local stress concentration, hinder the further occurrence of grain boundary slip, when the stress concentration can not be eliminated by dislocation movement, the cavity will nucleate, and then the occurrence of long Big. Voids preferentially nucleate at the triangular grain boundaries. As the amount of deformation increases, the voids really start to grow and the voids do not grow in an equiaxed manner, but rather grow in an oval manner. The voids tend to spread parallel to the stress-shared grain boundaries, forming oriented vacancies in the direction of tensile stress and accumulating toward the center of the void, allowing the voids to grow parallel to the direction of stretching. A large number of literatures mentioned the alloy forging process prone to "pitting" and hollow, TA7 titanium alloy by the "pitting" and the formation of holes defects mechanism analysis, we have summarized a set of TA7 titanium alloy to prevent cavities defects Effective way is to strictly control the amount of deformation per fire ≤ 50%, strictly control the deformation rate, the best hydraulic or hydraulic forging, try to avoid the use of hammer forging, and achieved good results in the production.

Forging thermal effect

Titanium alloy deformation at the transformation point (α + β / β transition temperature) to obtain the net basket or Wiesmann plasticity, poor fatigue performance, so the vast majority of titanium alloy product technical standards require near α, α + β Biphase titanium alloy products, the microstructure is generally better overall performance of the equiaxed or bimodal organization, so nearly α, α + β biphasic titanium alloy forgings generally choose the phase transition point below 30 ~ 60 ℃ Heating forging. Numerous studies and engineering practices have shown that as the forging heating temperature increases, the content of primary α-equiaxed in the microstructure of the dual phase titanium alloy decreases significantly, while the content of α-lath dramatically increases. That is to say, when the biphase titanium alloy is heated below the transformation temperature, as the heating temperature increases, the primary alpha-equiaxial phase in the structure gradually changes to the beta-phase, resulting in that the primary alpha-equiaxial phase in the titanium alloy microstructure after forging is heated Content decreased, the shape of the smaller, α lath content increased, when the heating forging temperature exceeds the transformation point of titanium alloy, dual-phase titanium alloy primary α-axis all disappear, as the strip-shaped basket tissue or Wei's tissue .

In forging deformation of titanium alloy, under normal circumstances the center is a violent deformation zone, so the center is the highest temperature rise in the central part of the temperature rise as the main basis for the development of the forging process. Forged titanium alloy forged with faster forging speed, must consider the central thermal effect during forging process, cannot hit the billet continuously. Titanium alloy forging in the conditions of the proposed press or fast forging machine, this type of forging equipment to combat speed is low, the blank forging process instantaneous strain rate is low, the deformation heat is not very obvious, and have enough time to deformation Thermal diffusion does not result in a significant increase in the instantaneous temperature of the heart.

3. Organization is not uniform

The microsegregation is due to the equilibrium partition coefficient k0> 1 or k0 <1. The segregation caused by the different solute concentrations in the crystallized region of the alloy belongs to the customary segregation. This segregation can hardly be completely avoided but can be checked by appropriate measures. On the one hand by optimizing the optimization of ingot melting process parameters to be controlled, on the other hand through the appropriate forging process to improve the elimination. Forging process, the first in the ingot billet forging, the use of appropriate high temperature homogenization treatment, for the ingot columnar microstructure of the intragranular dendrite segregation by homogenization annealing or deformation recrystallization to improve and eliminate; followed by the alloy Billet and finished product die forging process using forging cooling method to be controlled to inhibit the appearance of coarse α block in the microstructure. The above TC17 titanium alloy forging in the sub-β forging, the use of air-cooled coarse block it is the cause of the block, after forging cooling slow, low degree of undercooling, low nucleation rate, so the α phase has enough time to grow up to form a large α Piece.