Titanium welded pipe introduction

Since the 1930s, with the rapid development of high quality strip and strip production and the progress of welding and inspection technology, the quality of the weld seam has been constantly improved. The varieties and specifications of the titanium alloy plate have been increasing day by day, and have replaced more and more fields Seamless titanium tube.

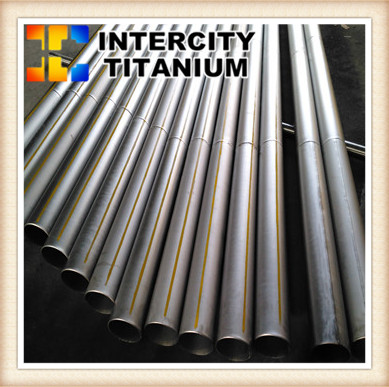

Tubes made of titanium alloy plate, also known as titanium tube, is composed of titanium or titanium with a curved tube after welding. Titanium alloy plate production process is simple, high production efficiency, variety specifications, less equipment investment, but the overall strength is lower than the seamless titanium tube.

Titanium alloy plate according to the form of welding is divided into straight seam titanium tube and titanium tube. Straight seam titanium pipe production process is simple, high production efficiency, low cost and rapid development. The strength of the spiral titanium tube is generally higher than the vertical seam titanium tube, with a narrow billet can produce larger diameter titanium tube, you can also use the same width of the billet production of different diameter titanium tube. However, compared with the equivalent length of straight pipe, weld length increased by 30 ~ 100%, and the production rate is low. Therefore, smaller diameter titanium tubes are mostly used for straight seam welding, large-diameter titanium tubes are mostly spiral welded.