|

Products |

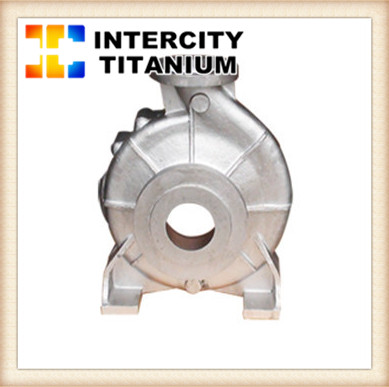

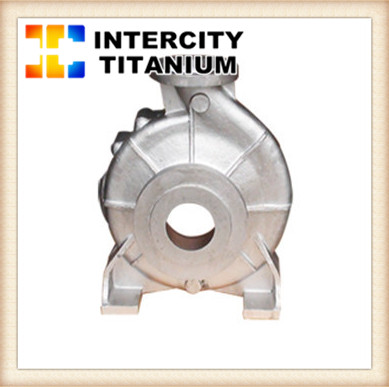

Titanium and Titanium alloy Castings |

|

Grade |

GR1,GR2,GR5,GR7,GR12(TA1,TA2,TC4,TA9,TA10) |

|

Standard |

ASTM B367 |

|

Advantages |

1.We are located at Titanium vally of China-Baoji 2.We have complete equipment of casting 3.Our Specialists team guarantee the high quality 4.Products Inspection:Ultrasonic wave and X-ray100% test 5.Rough moulding and finished products both we can supply |

|

Application |

Industrial, Metallurgy, Pump, Valve,etc |

|

Main products |

Titanium Valve,Titanium Valve Parts,Titanium Pump Parts Other Titanium Casting Products |

We can also do the other titanium castings as your drawings

Shell Making

Pouring

Material:Titanium and Titanium alloy

Characteristics:High strength light weight corrosion resistant

Standard:ASTM DIN ISO or other required standards.

Casting tolerance:ISO 8062 CT6-CT10

Capabilities:Several vacuum arc melting and pouring units From 80kg to 500kg liquid titanium per pour Maximum Single Cast Weight 400kg Can make pattern quickly ,shorten deliver time

Applications:Airplane ship auto chemical medical sport

Inspection

Surface Check:MSS SP55 Surface defects visual detection

Dimension Check:ISO 8062 Dimensions check: Wax CT6 EPS CT8 Gr CT10

Finish dimension: ISO 2768 Only for freedom tolerance

X-Ray Test : ASME VIII Div.1 .App.7 Casting internal defects test

NDT Test LPE Test: ASME VIII Div.1 .App.7 Casting surface defects test

UT Test : ASME V Casting internal defects and position test, casting thickness measure

Precision Casting

Investment casting (also known as lost wax casting) is a precision casting methodology that can be used over the widest range of metal types .

Tuopusen manufactures castings ranging from a few grams (about 0.1 oz) in weight to about 400 kg (880 lb). The minimum wall thickness are 0.06cm(0.024 in) .The size can be cast under 200cm X(78in) 100cm(39in).

Machining

We provide a full range of machining services to complement the range of alloys used in our casting process and deliver fully finished items or assemblies. such as milling, turning, gear cutting and grinding operations.

CNC lathe & vertical lathe

CNC boring machine

CNC horizontal machining center

Heat Treatment

General Heat Treatment

Annealing, stress relieving,tempering etc.

Vacuum Furnace

Vacuum heat treating is used for bright hardening and tempering, bright annealing

Surface Finishing

We offer several surface finishing options.

Polishing – by hand and automated

Pickling - by assembly line

Abrasive blasting - by assembly line

Inspection & Testing