Application of Titanium in Medical Transplantation

Titanium in transplantation applications

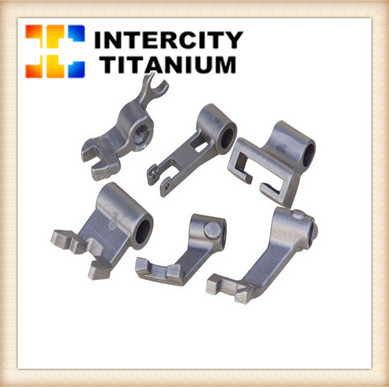

Artificial joints and artificial bone substitute materials should have the following basic properties: Lightweight high strength materials, with biocompatibility, corrosion resistance, implant in the body of the tissue reaction does not cause deterioration of the material, caused by repeated stress Fatigue, less damage and other properties. The most important properties of metal implants are formability, machinability and profitability, which must remain functional over their expected lifetime, not deteriorate when subjected to fatigue, wear, corrosion and shock loading, and titanium and titanium alloys conform to all the above requirements. The earliest use of dental powder, polypropylene, plexiglass and other artificial joint material of low strength, easy to fold, poor biocompatibility. Later switched to stainless steel, but a larger proportion of stainless steel, about 2 times the proportion of the human skeleton, but also in vivo role of body fluids will appear corrosion and fracture. Co-Cr alloy is also an excellent artificial joint material, but unfortunately, cobalt, chromium is toxic to humans. The small proportion of titanium and titanium alloys (similar to the proportion of human bone), strength, mechanical processing, corrosion resistance is excellent, is an ideal imitation joint material.

Surgical graft material is used in the provision of titanium and titanium Ti-6Al-4VELI alloy based. Recently, the grafts Ti-6Al-7Nb and Ti-13Nb1-13Zr, which have good compatibility with the human body, have also obtained the ASTM standards. Titanium artificial bone, cells can be regenerated on it, the bones can grow, titanium and the human body bone, epithelium, to create a moral affinity with the organization. In order to improve the surface quality of implants attached to human bones, biomedical coatings on roughened surfaces are also more effective methods. At present, titanium and titanium alloys have been widely used in artificial bone and joint, artificial bone, joint plate, a broken bone anchor, intramuscularly nail, an artificial heart valve, skull and so on. Depending on statistics, the annual demand for titanium alloy artificial joints in China exceeds 5000 sets, and the clinical application is good.

Application of titanium in orthopedic surgery

Medical titanium alloy elastic modulus closer to human bones than stainless steel, suitable for humanoid orthopedic surgery. In orthopedic surgery, the use of titanium nickel shapes memory alloy. The research shows that NT-SMA is a new material that combines wear resistance, decay resistance, the shape memory effect, pseudo-elasticity and acoustic damping. It is commonly used in orthopedics. In addition to commonly used bone plate, intramuscularly nail, Fixed, scoliosis correction and so on, Shanghai Changhai Hospital and NT-SMA was a series of design and clinical applications, such as NT-patellar device, NT-arc fork nail, NT-bow, NT-fly Designed for sacral reconstruction), and achieved satisfactory results. For titanium alloy materials applied to the human body, countries are still constantly just trying to explore and seek more safe and reliable new titanium alloy for the benefit of people all over the world.

Titanium in the pharmaceutical industry

Titanium in the pharmaceutical industry is primarily used for making containers, reactors and heaters. In pharmaceutical production, the equipment often comes into contact with inorganic acids such as hydrochloric acid, nitric acid and sulfuric acid, organic acids and their salts, the equipment is often damaged due to corrosion, and the iron ion pollution brought by the steel equipment affects the product quality. Titanium equipment you can solve these problems. For example, penicillin esterification reactor, saccharification tank, chloramphenicol thin film evaporator, miconazole reactor, Mitur filter, dimethyl sulfate cooler, liquid filter, etc., have the precedent of titanium materials, The quantity and quality of the liquid produced are continuously improved, and the quality fully complies with the provisions of the Chinese Pharmacopoeia.

Titanium in Medical Devices

Titanium and titanium alloys have good corrosion resistance, titanium non-toxic, non-magnetic, is a good choice of medicinal equipment materials. In the history of the development of surgical instruments, the first generation of surgical instruments made of carbon steel, due to the performance of the plated less than clinical requirements and be eliminated. The second generation of austenitic, ferritic and martensitic stainless steel surgical instruments, but the composition of chromium in the stainless steel is toxic, shedding of chrome layer has a certain impact on the human body, therefore, the emergence of the third generation - titanium surgical instruments. Titanium has the lightweight characteristics, making it particularly suitable for microsurgery. Titanium is resistant to corrosion, good elasticity, no deformation, etc., resistant to repeated cleaning, disinfection of the surface quality is not affected; non-magnetic, can exclude the tiny, sensitive to the threat of damage to implanted electronic devices and other characteristics of titanium surgical instruments more and more applications The more widely. Has been used to make surgical blades, hemostats, scissors, electric bone drilling, tweezers and so on? Titanium vascular suture needle in the medical equipment, sternal suture, one of the cardiac surgical instruments oxygen filter titanium filter, electrocardiogram machine with titanium electrodes, in vitro culture machine with titanium incubator; medical ultrasonic crushing Machine probe, blood transport box automatic controller, as well as for ophthalmic surgery titanium equipment, the current situation is good.

Dental applications of titanium and titanium alloys

Owing to titanium has excellent corrosion resistance and human affinity, and considering the metal allergy and specific strength suitable for dental applications. The metal used in dental surgery, starting from the amalgam and metal crowns of the 1920s, mainly used gold, silver and palladium alloys in the 1960s and the permanent and removable instruments for orthodontics after the seventies The most commonly used materials, the nineties titanium casting technology to promote the application. Dental Titanium casting machine casting with high dimensional accuracy, no bubbles and shrinkage and other characteristics of metal materials used in human hard tissue repair, titanium elastic modulus and tissue closest to the body, which can reduce the metal implant and bone Mechanical incompatibility between tissues. The thermal conductivity of titanium is the lowest of all dental restorative metal and the low thermal conductivity can reduce the thermal stimulation of the dental pulp of a tooth with a crown, which is important for tooth repair. Titanium inlay, such as the crown with the protection of dental pulp, to avoid the role of hot and cold stimuli. Dental titanium in the material, the original mostly titanium, but its strength is not enough, it is difficult to grind, there is inferior wear resistance, easy to produce casting defects and unstable quality and so on. Ti-6Al-4V alloys are the most commonly utilized Ti-6Al-4V alloys. However, Ti-6Al-4N alloy has been developed because of the harmful effect of metal V on the human body and Nb instead of V, which has excellent corrosion resistance. The mortal body basically harmless, but also has strong plasticity, excellent grinding and other advantages, has achieved ASTM standards. Currently super-elastic Ti-Ni alloy is commonly used in dental straightening. Developed countries from the 1980s began to study the application of titanium in the restoration of the mouth, first for dental implants, and later for dentures, crowns and orthodontic teeth, titanium can be used for dental crown, nail , Fixed bridge, porcelain bridge, bond bridge, denture clasp, base, connecting device and strengthening device, almost all the metal parts of denture can be made of titanium. The research of titanium and titanium alloy has become a hot spot in the research of dental application alloy. Titanium porcelain teeth can restore the dental body morphology and function well, and high-strength, beautiful appearance, color stability, smooth surface, wear resistance, corrosion resistance, is a permanent restoration for all fixed teeth, Especially its biocompatibility, nickel-sensitive people more suitable, it has been widely used in dental restoration.